Scientific Molding

Scientific Molding

For many years, Winzeler Gear has embraced the science of decoupled scientific molding with extensive training and collaboration with RJG. The proper execution of scientific molding is critical to maintaining and documenting consistent quality production for a gear with high tolerances and demanding structural and dimensional stability requirements.

How scientific molding works:

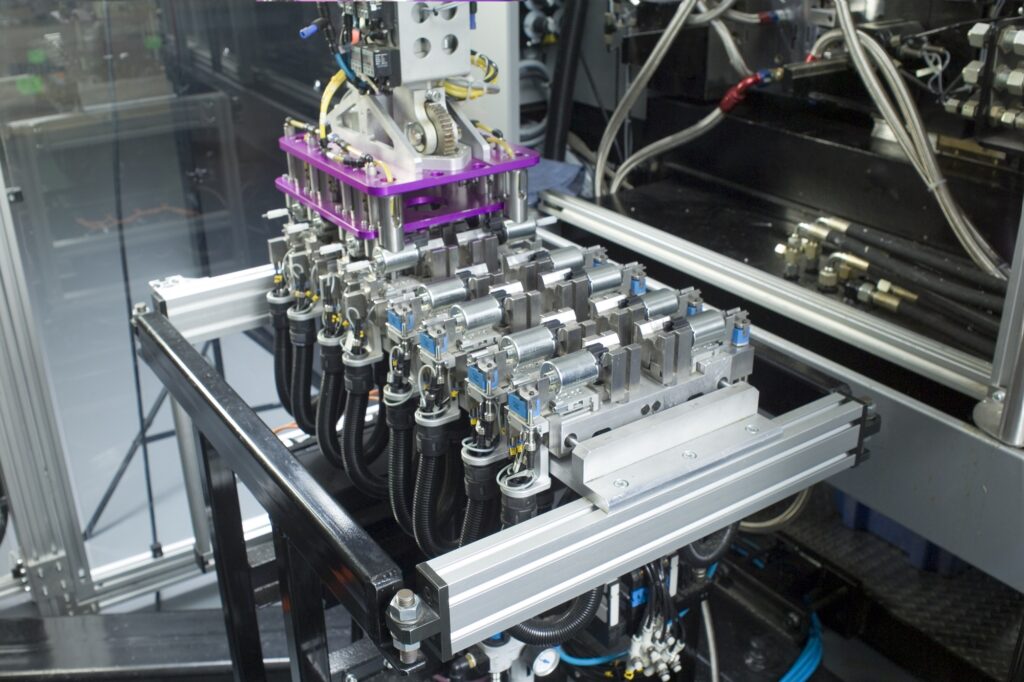

- Every prototype and production cavity developed includes a pressure sensor, which ensures minimum variability in gear dimensions and material integrity.

- Molding processes are based upon the plastic behavior in the cavity – cavity pressure curves are date stamped and stored on the company server.

- If a gear fails to meet cavity pressure tolerances, it automatically gets rejected.

- Once approved, gears are then picked by a robot, placed on a conveyor, or placed in a carton.

Our vision for the future of automation at Winzeler Gear is Industry 4.0 data analytics, which will facilitate the optimization of processes. From prototyping to production, Winzeler Gear will always ensure all your molded gears perform consistently with the help of our data-driven scientific molding process.

Contact the experts at Winzeler Gear today to learn more.