Gear Gizmo

Gear Gizmo

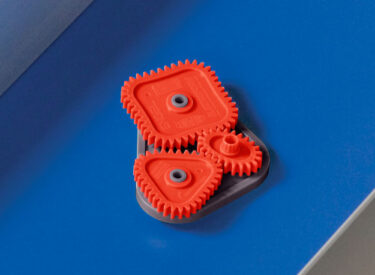

Incompatible Shapes Working Together to Create Something New

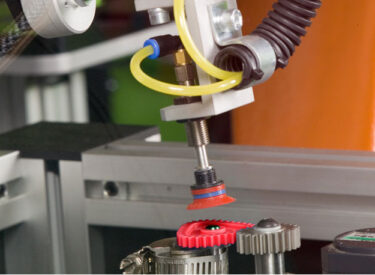

At first glance, a square, an elliptical and a triangular gear meshing together doesn’t seem like a functional gear assembly. However, Winzeler Gear believes nothing is impossible when it comes to gear design. In 2004, our team worked together with our strategic partners DuPont Performance Polymers, RJG, and Engel North America to officially bring the Gear Gizmo to life.

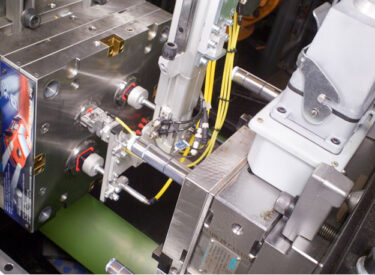

Winzeler Gear’s Director of Manufacturing, Harry Soling, met with Engel North America President, Walter Jungwirth, and RJG President Rod Groleau, to discuss the production of the Gear Gizmo. Engel and RJG shared Winzeler’s vision of creating the unique gear assembly, but they needed a better understanding of how RJG telemetry could interface with Engel’s molding press technology. They began brainstorming on how they could best demonstrate their mutual development of molding technology in time for the 2006 NPE show.

The first version of the Gear Gizmo was initially developed as an elliptical gear that would mate with a triangular gear. To make the design more challenging, he and his strategic partners worked together to add a square gear that also meshed with the other gears, thus creating the initial prototype of the Gear Gizmo. Mold construction began in January 2006, just after Engel completed work on the RJG interface. With the gear design in place, Soling completed initial process development, and shipped the mold along with the RJG interface to Engel for final assembly and integration.

The demonstration at NPE 2006 was a tremendous success, proving that all the companies contributing their own imagination, experience, and passion were able to bring a shared vision to life.